The Evolution and Importance of China Plastic Mold in Metal Fabrication

In today's rapidly changing industrial landscape, metal fabricators face a plethora of challenges ranging from increasing competition to the demand for innovation and efficiency. Among the innovative solutions that have emerged, China plastic mold technology has become a cornerstone in modern metal fabrication processes. This article delves into the pivotal role that this technology plays and how it can benefit businesses in the metal fabrication sector.

Understanding Plastic Molding Technology

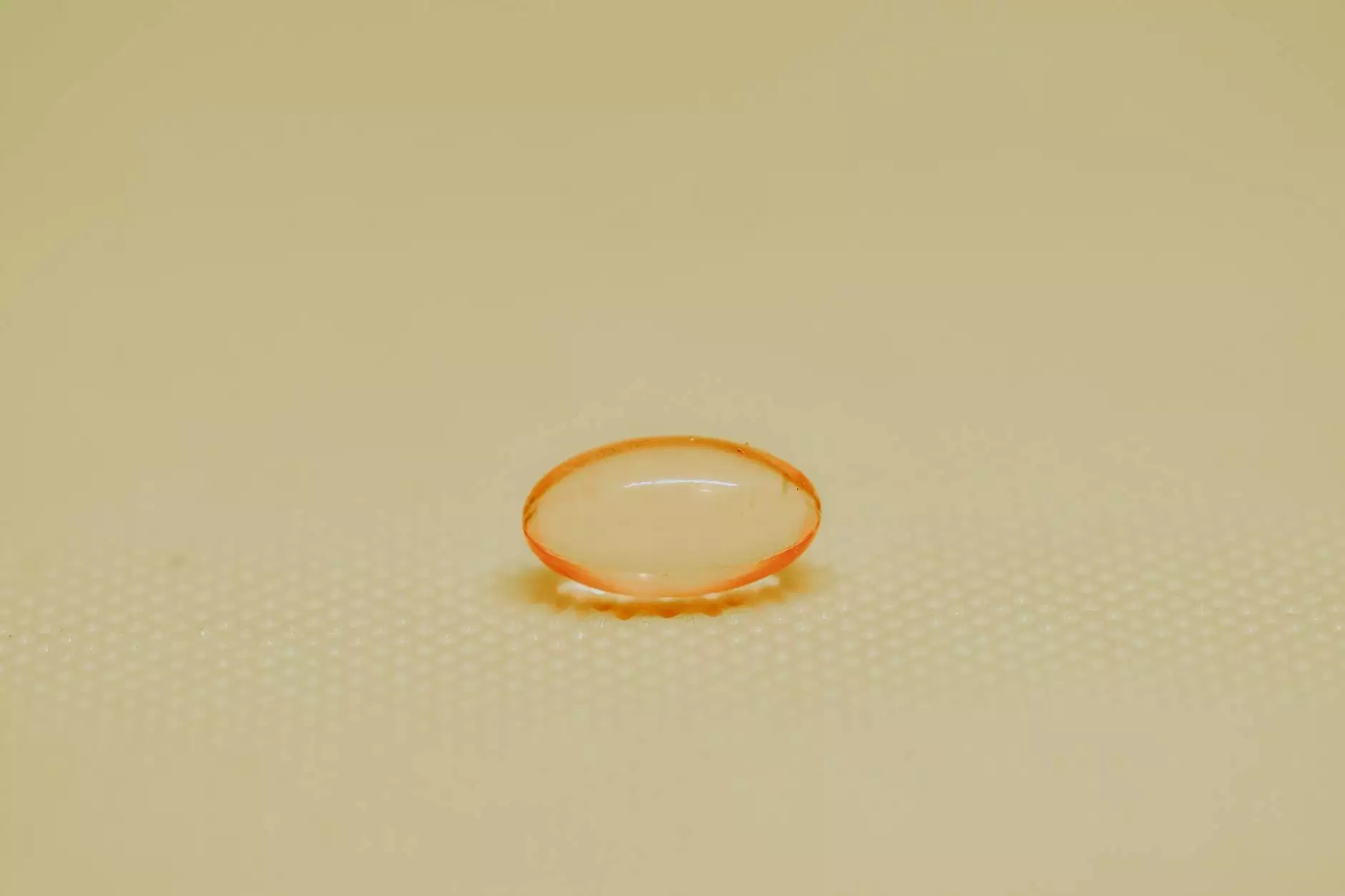

Plastic molding, particularly in the context of metal fabrication, involves a process where molten plastic is injected into a mold, cooled, and then solidified to create precise components. China plastic mold technology has garnered a reputation for its efficiency and quality, providing manufacturers with the ability to create intricate parts at scale.

Types of Plastic Molding Processes

- Injection Molding: The most common method where plastic is injected into a mold under pressure.

- Blow Molding: Used for creating hollow plastic parts, such as bottles.

- Extrusion Molding: A continuous process where plastic is melted and formed into long shapes.

- Rotational Molding: Involves rotating a mold around two axes to create large, hollow parts.

The Benefits of Using China Plastic Mold

China's advancements in plastic molding technology are significant. Here are some of the benefits that encapsulate why China plastic mold is a superior choice for metal fabricators:

1. Cost-Effectiveness

One of the most significant advantages of sourcing molds from China is the cost-effectiveness. The labor and material costs in China are lower than in many Western countries, allowing businesses to save substantially on manufacturing expenses. This cost reduction can be reinvested into other areas of the business, leading to further growth.

2. High-Quality Production

Despite the lower costs, the quality of China plastic mold products is often on par with, if not superior to, that of other countries. Chinese manufacturers utilize cutting-edge technology and quality control measures to ensure that the molds produced are durable, precise, and meet international standards.

3. Wide Range of Materials

China's extensive manufacturing capabilities allow for a diverse selection of materials. Whether your project requires standard thermoplastics, specialized resins, or blended materials, China plastic mold manufacturers can provide the exact specifications needed for your unique applications.

4. Quick Turnaround Times

Efficiency is a hallmark of Chinese manufacturing. With streamlined production processes, companies can achieve quick turnaround times, getting your molds ready and delivered in a fraction of the time required elsewhere. This rapid production cycle helps businesses to maintain an agile operation, responding swiftly to market demands.

5. Customization and Flexibility

Chinese manufacturers are well-versed in providing customized solutions tailored to specific client needs. This flexibility ensures that every business, regardless of size or industry, can find a suitable mold for their requirements.

Key Applications of China Plastic Mold in Metal Fabrication

In the realm of metal fabrication, China plastic mold technology is utilized across various industries. Some key applications include:

- Automotive Industry: Molds are used to create lightweight components that enhance fuel efficiency and reduce emissions.

- Electronics: Precise and intricate parts for devices, ensuring quality and reliability.

- Aerospace: Aerospace manufacturers rely on high-strength components created through advanced mold techniques.

- Consumer Goods: Delivers innovative designs and high-volume production capabilities for everyday products.

The Environmental Impact of China Plastic Mold Technology

As sustainability becomes a priority globally, the China plastic mold industry is also advancing towards greener practices. Manufacturers are adopting eco-friendly materials and processes to minimize waste and reduce environmental impact.

1. Utilizing Recycled Materials

Many Chinese mold manufacturers are now using recycled plastics in their production processes, significantly lowering the carbon footprint associated with plastic production.

2. Energy Efficiency

Advanced manufacturing technologies not only enhance efficiency but also reduce energy consumption, making it a win-win for both organizations and the environment.

3. Waste Reduction Strategies

Smart manufacturing techniques focus on minimizing waste generation, optimizing the use of raw materials in production processes, further contributing to environmental sustainability.

Challenges Faced in the Industry and Solutions

While China plastic mold technology presents numerous benefits, there are also challenges that the industry must navigate:

1. Quality Control

Ensuring consistent quality across production runs is crucial. It is essential to collaborate with reputable mold manufacturers who implement rigorous quality assurance processes.

2. Communication Barriers

Differences in language and business culture can lead to misunderstandings. Establishing clear communication channels and hiring bilingual professionals can alleviate this issue.

3. Intellectual Property Concerns

Companies must ensure that their designs and technologies are protected when outsourcing to foreign manufacturers. This may involve thorough agreements and legal protections to guard Intellectual Property (IP).

Future Trends in China Plastic Mold Technology

The future of China plastic mold technology is filled with exciting possibilities. Here are some trends to watch:

1. Automation and Robotics

As industries look to improve efficiency and production speed, the integration of automation and robotics in the molding process becomes more prevalent. This advancement will lead to reduced labor costs and increased output.

2. 3D Printing Integration

3D printing technologies are being integrated with traditional molding techniques to create rapid prototypes and short-run productions, drastically shortening the development cycle.

3. Advanced Materials Development

Research into new materials that are both lightweight and durable will influence the future of manufacturing. Innovations in nanotechnology and composites will likely reshape product design.

4. Sustainable Practices Expansion

As global demand for sustainable practices rises, the China plastic mold industry will continue to evolve, focusing on eco-friendly materials and processes.

Conclusion: Embracing the Power of China Plastic Mold

As the metal fabrication landscape continues to evolve, China plastic mold technology stands out as a pivotal solution for enhancing productivity and driving innovation. By understanding the benefits, applications, and future directions of this technology, businesses can better position themselves for success in a competitive marketplace. For expert insights and tailored solutions, visit DeepMould.net and explore how our state-of-the-art plastic mold solutions can meet your needs.